Steel Plasma

Manual coping requires that you perform every step manually, from reading the drawings to transferring dimensions, framing and cutting beams with a torch handheld. Manual coping requires a lot of grinding and chipping in order to get the desired result. There is also the possibility of human error in terms of angles, finish, dimensions and misalignment. These inefficiencies can increase operational costs and reduce profits.

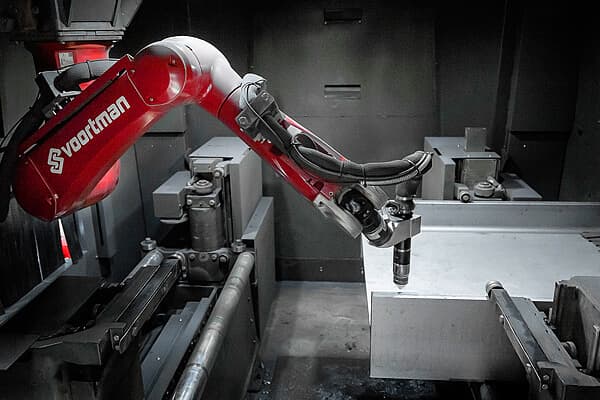

Voortman's V808 doesn�t require a clean cut when nesting new products. It is possible to reduce scrap by using this method. Also, the last cut from a product is the first cut of the next one. The V808 is able to import DSTV+ or VACAM's beam nesting modules to create continuous nestings. You can get more product out of every stock length and reduce costs.